Walk-in Freezer Wiring Diagram PDF: A Comprehensive Guide

Navigating walk-in freezer electrical systems requires detailed PDFs, offering schematics for components like compressors and defrost timers, crucial for maintenance and troubleshooting.

Understanding Walk-in Freezer Systems

Walk-in freezers are complex refrigeration systems, relying on precise electrical control for consistent temperatures. These systems integrate several key components – compressors, evaporators, condensers, defrost systems, and temperature controllers – all interconnected via a network of wiring.

A thorough understanding of these systems is paramount before attempting any electrical work. Wiring diagrams serve as the roadmap, illustrating how these components interact; Proper functionality hinges on correct wiring, ensuring efficient operation and preventing costly downtime. PDF versions of these diagrams are invaluable for accessibility and preservation, offering a portable and reliable reference for technicians and maintenance personnel.

Effective troubleshooting demands familiarity with the system’s electrical layout, making wiring diagrams essential tools.

Components of a Typical Walk-in Freezer

A standard walk-in freezer comprises several critical electrical components. The compressor, the heart of the system, requires specific wiring for power and control. Defrost timers manage ice buildup, necessitating dedicated circuits; Temperature controllers, like the Dixell XR06CX, regulate cooling via sensor inputs and relay outputs.

Fan motors circulate air for even temperature distribution, each needing individual wiring; Door heaters prevent frost accumulation around door seals, demanding separate power lines. These components are interconnected through a complex wiring network, detailed in the freezer’s wiring diagram PDF.

Understanding each component’s function and its place within the electrical scheme is vital for effective maintenance and repair.

Importance of a Wiring Diagram

A walk-in freezer wiring diagram PDF is indispensable for anyone working with these systems. It provides a visual roadmap of the electrical connections, simplifying troubleshooting and repairs. Without a diagram, identifying wires and components can be a daunting task, potentially leading to incorrect connections and system failures.

Accurate diagrams ensure safe and efficient maintenance, minimizing downtime and preventing costly repairs. They are crucial for understanding the interaction between components like compressors, defrost timers, and temperature controllers. Having a readily available PDF allows technicians to quickly diagnose issues, replace faulty parts, and verify proper operation.

Ultimately, a wiring diagram is a safety and efficiency tool.

Essential Wiring Diagram Elements

Key elements in a walk-in freezer wiring diagram PDF include compressor, defrost timer, temperature controller, fan motor, and door heater schematics for clarity.

Compressor Wiring

Understanding compressor wiring is fundamental when reviewing a walk-in freezer wiring diagram PDF. Typically, diagrams illustrate the connection of the compressor to the contactor, overload protection, and the power supply.

The diagram will detail the wiring for the compressor’s three phases (L1, L2, L3) and the common connection. Pay close attention to the thermal overload relay, which protects the compressor from overheating; its wiring is critical.

A fused disconnect switch, often shown near the compressor, provides a safety shut-off point. The PDF should clearly indicate wire gauges and color coding for proper installation and troubleshooting.

Correct wiring ensures efficient cooling and prevents damage to the compressor, a costly component to replace.

Defrost Timer Wiring

A walk-in freezer wiring diagram PDF will detail the defrost timer’s intricate connections, essential for automated ice removal. The timer controls the defrost cycle, activating the defrost heater and terminating the compressor.

Diagrams illustrate wiring to the defrost heater, a termination thermostat, and a defrost water drain. The timer’s various terminals (e.g., L1, L2, T1, T2) are clearly labeled, showing how it switches power to these components.

Understanding the timer’s cycle – defrost, off, and cooling – is crucial. The PDF should show the wiring sequence for each phase.

Proper wiring ensures efficient defrosting and prevents ice buildup, maintaining optimal freezer performance. Incorrect connections can lead to heater failure or continuous defrost cycles.

Temperature Controller Wiring (Dixell XR06CX Example)

Walk-in freezer wiring diagram PDFs frequently showcase the Dixell XR06CX controller, a popular choice for precise temperature management. These diagrams detail connections for the temperature probe, compressor relay, defrost relay, and alarm outputs.

The PDF illustrates wiring for power supply (L, N), digital inputs, and relay outputs. Understanding the controller’s terminal designations (e.g., 1, 2, 3, 4, 5, 6) is vital for correct installation.

Wiring diagrams show how the XR06CX receives temperature readings and activates/deactivates cooling and defrost cycles.

Proper wiring ensures accurate temperature control, preventing spoilage and optimizing energy efficiency. Incorrect connections can lead to inaccurate readings or malfunctioning components.

Fan Motor Wiring

Walk-in freezer wiring diagram PDFs clearly illustrate fan motor connections, essential for air circulation and temperature uniformity. These diagrams typically depict single-phase or three-phase motor wiring, depending on the system’s capacity.

The PDF will show wiring for the fan motor capacitor, overload protection, and the power supply. Diagrams detail connections to the fan motor’s terminals, often labeled with voltage and amperage specifications.

Understanding the wiring configuration is crucial for replacing or repairing fan motors.

Correct wiring ensures proper fan operation, preventing temperature stratification and maintaining consistent cooling. Incorrect wiring can cause motor failure or inefficient cooling performance.

Door Heater Wiring

Walk-in freezer wiring diagram PDFs detail the door heater circuit, vital for preventing ice buildup around door perimeters. These diagrams illustrate the wiring for electric door heaters, commonly used to maintain a seal and ease door operation.

The PDF will show connections to the power supply, a thermostat, and the heater element itself. Diagrams often include wiring for safety features like overload protection and high-limit switches.

Understanding the wiring is essential for troubleshooting door heater malfunctions.

Correct wiring ensures the heater effectively prevents ice formation, maintaining a proper door seal and reducing energy loss. Faulty wiring can lead to ice buildup, making the door difficult to open and compromising freezer efficiency.

Types of Wiring Diagrams

Walk-in freezer PDFs present schematic, power, and control circuit diagrams, each offering a unique perspective on the electrical system’s layout and functionality.

Schematic Diagrams

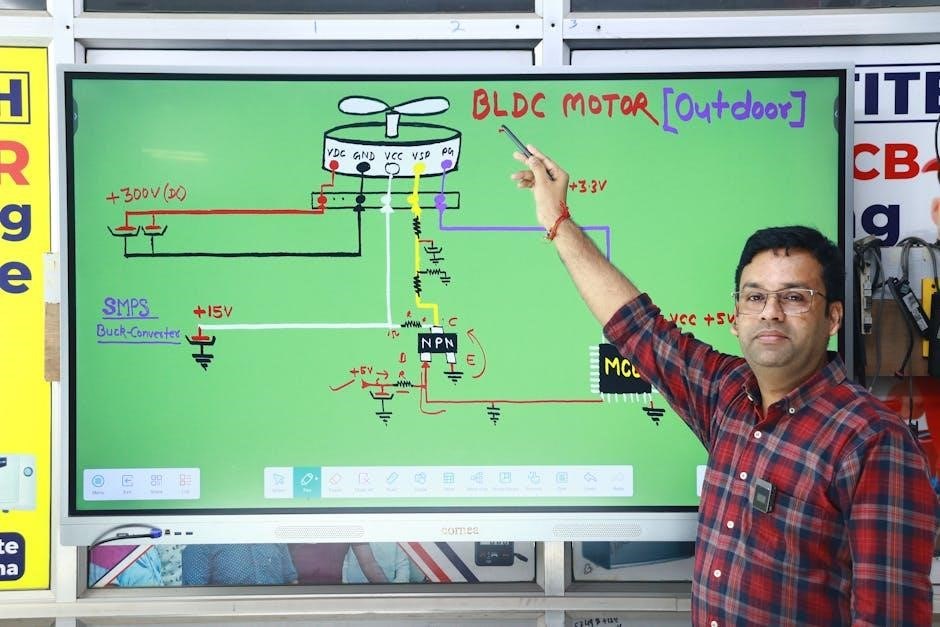

Schematic diagrams, found within walk-in freezer wiring diagram PDFs, utilize standardized symbols to illustrate the functional relationships of electrical components; These aren’t concerned with physical placement; instead, they focus on how electricity flows through the system.

Think of them as a roadmap of the electrical logic. A typical schematic will depict the compressor, defrost timer, temperature controller (like a Dixell XR06CX), fan motors, and door heaters, alongside essential elements like thermal overload protectors and disconnect switches.

Understanding these diagrams requires familiarity with electrical symbols. They are invaluable for tracing circuits, identifying potential faults, and planning modifications. These diagrams are often the first point of reference for technicians diagnosing issues within the freezer’s electrical infrastructure.

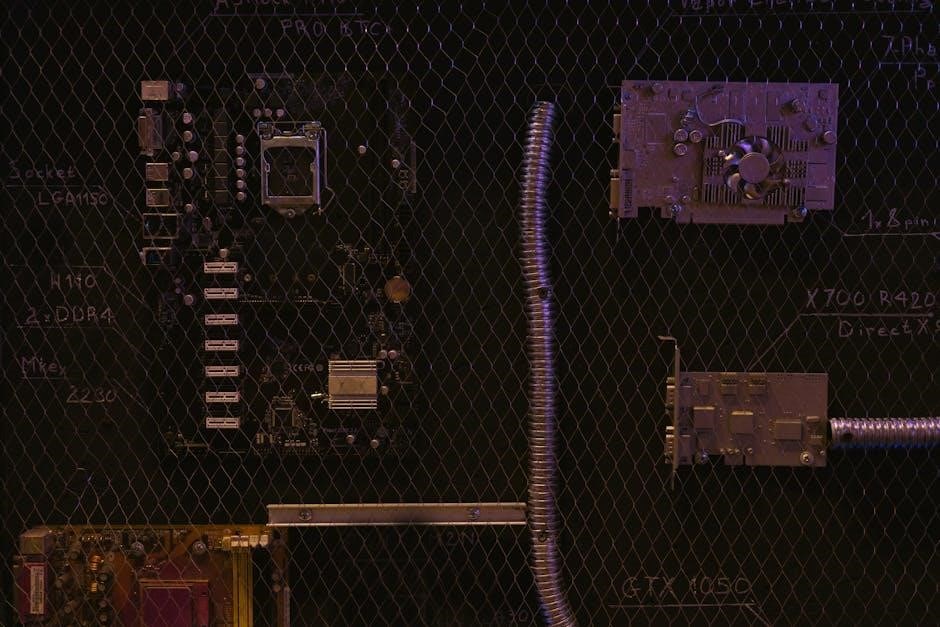

Power Wiring Diagrams

Power wiring diagrams, integral to walk-in freezer wiring diagram PDFs, illustrate the physical layout of high-voltage electrical connections. Unlike schematic diagrams, these focus on where wires are run and connected, showing the actual physical arrangement of components.

These diagrams detail the wiring from the fused disconnect switch – a critical safety component – to the compressor, heaters, and control panels. They specify wire gauges, conduit runs, and connection points. Understanding these diagrams is vital for safe installation and maintenance, ensuring proper voltage delivery to each component.

They often include details about grounding requirements and the location of thermal overload protection devices. Technicians use these diagrams to verify correct wiring and identify potential hazards related to power distribution.

Control Circuit Diagrams

Control circuit diagrams, found within walk-in freezer wiring diagram PDFs, depict the low-voltage wiring that governs the freezer’s operation. These diagrams illustrate how components like the temperature controller (e.g., Dixell XR06CX), defrost timer, and fan motors interact.

They focus on the logic and sequencing of operations, showing how signals are sent between components to initiate defrost cycles, activate fans, or regulate compressor runtime. Understanding these diagrams is crucial for diagnosing control system malfunctions.

These diagrams utilize symbols representing relays, sensors, and timers, detailing their interconnection. Technicians use them to trace signal paths and identify faulty components within the control system, ensuring precise temperature management.

Safety Precautions for Wiring

Prioritize safety! Walk-in freezer wiring demands lockout/tagout procedures, voltage testing, and proper grounding—essential precautions detailed in wiring diagram PDFs.

Lockout/Tagout Procedures

Implementing robust lockout/tagout procedures is paramount when servicing walk-in freezer electrical systems. Before accessing any wiring, always disconnect the main power supply and verify it’s de-energized using a reliable voltage tester.

Refer to the walk-in freezer wiring diagram PDF to identify the correct disconnect points. Apply a lockout device to the breaker or disconnect switch, ensuring it cannot be accidentally re-energized. Attach a tag clearly stating “Do Not Operate” and the reason for the lockout.

This prevents unexpected energization during maintenance, safeguarding technicians from electrical shock. Confirm all personnel are aware of the lockout/tagout in place. Proper documentation of the procedure, often referenced within comprehensive wiring diagram PDFs, is also crucial for safety compliance.

Voltage Testing

Accurate voltage testing is a non-negotiable step before and during work on walk-in freezer wiring. Always utilize a calibrated multimeter, ensuring it’s set to the appropriate voltage range as indicated in the wiring diagram PDF. Verify the absence of voltage at all intended work points after implementing lockout/tagout procedures.

Referencing the wiring diagram PDF helps identify expected voltage levels at specific components – compressor, defrost timer, or fan motors – allowing for quick detection of anomalies. Test both line-to-line and line-to-ground to confirm complete de-energization.

Never assume a wire is dead; always test it. Document all voltage readings for troubleshooting and safety records. A reliable voltage reading confirms a safe working environment.

Grounding Requirements

Proper grounding is paramount for safety and operational integrity within walk-in freezer systems. The wiring diagram PDF will illustrate grounding points, typically connected to the equipment chassis and the building’s grounding system. A robust ground path minimizes electrical shock hazards and protects sensitive components from voltage spikes.

Ensure all metal enclosures, including the freezer itself, are effectively grounded. Verify grounding connections are clean, tight, and free from corrosion. The diagram PDF should detail the appropriate wire gauge for grounding conductors, adhering to local electrical codes.

Regularly inspect grounding connections and test for continuity to the ground. A faulty ground can lead to equipment failure and create dangerous conditions. Prioritize grounding for a safe and reliable system.

Common Wiring Issues & Troubleshooting

Wiring diagram PDFs aid in diagnosing issues like tripped breakers, defrost timer failures, and compressor overloads, enabling efficient repairs and minimizing downtime.

Tripped Breakers

Frequent breaker trips within a walk-in freezer system, as detailed in wiring diagram PDFs, often signal an overload or short circuit. A diagram helps pinpoint the affected circuit, potentially isolating issues to the compressor, fan motors, or defrost heaters.

Before resetting a breaker, the PDF guides users to investigate the cause – a faulty component or excessive load. Ignoring the root cause risks further damage and repeated interruptions. Utilizing the diagram, technicians can systematically test components, checking for continuity and proper resistance.

Overloads can stem from a failing compressor or a jammed evaporator fan. Short circuits, indicated by immediate tripping, require careful inspection of wiring for damaged insulation. The wiring diagram PDF is invaluable for tracing the circuit and identifying the fault location, ensuring safe and effective repairs.

Faulty Defrost Timers

Defrost timers, crucial for ice buildup prevention, often malfunction in walk-in freezers, as illustrated in wiring diagram PDFs. A faulty timer can cause excessive icing, reducing cooling efficiency and potentially damaging the evaporator coil. The diagram aids in tracing the timer’s control circuit, verifying power supply and signal connections.

Symptoms include inconsistent defrost cycles or complete failure to initiate defrost. Using the wiring diagram, technicians can test the timer’s internal components, checking for continuity and proper operation of relays. PDFs often show the timer’s wiring configuration, simplifying troubleshooting.

Incorrect timer settings or a failed heating element can mimic timer failure. The diagram helps differentiate between these issues, guiding accurate diagnosis and repair. Properly functioning defrost cycles are vital for maintaining freezer performance, and the wiring diagram is key to ensuring this.

Compressor Overload Protection

Compressor overload protection is vital, preventing motor damage from excessive current draw, and is clearly detailed in walk-in freezer wiring diagram PDFs. These diagrams illustrate the overload relay’s placement within the compressor circuit, showing connections to the contactor and power supply. Understanding this wiring is crucial for diagnosing compressor issues.

Overloads typically trip due to overheating, caused by blocked condensers or refrigerant issues. The PDF helps trace the circuit, verifying proper voltage and amperage levels. Resetting a tripped overload without addressing the root cause leads to repeated failures.

Wiring diagrams highlight the overload’s reset button and test points. Technicians use these to confirm the overload’s functionality and identify potential wiring faults. Proper overload protection ensures compressor longevity and prevents costly repairs, making the diagram an invaluable resource.

Resources for Finding Wiring Diagrams

Locate walk-in freezer wiring diagrams via manufacturer websites (like U.S. Cooler), HVACR forums, and specialized online databases offering downloadable PDFs.

Manufacturer Websites (U;S. Cooler Example)

Directly accessing manufacturer websites is often the most reliable method for obtaining accurate walk-in freezer wiring diagrams. Companies like U.S. Cooler frequently provide detailed technical documentation, including PDF schematics, specifically for their units.

These diagrams are typically found within the “Support” or “Resources” sections of their websites. Look for model-specific documentation, as wiring configurations can vary significantly even within the same manufacturer’s product line. U.S. Cooler’s diagrams often include detailed illustrations of component placement and wiring connections, aiding in troubleshooting and repair.

Registration may be required to access certain documents. Always prioritize manufacturer-provided diagrams as they reflect the exact wiring setup for that particular equipment, ensuring safety and accuracy during any electrical work.

HVACR Forums & Communities

HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) forums and online communities represent valuable resources for locating walk-in freezer wiring diagrams. Experienced technicians frequently share diagrams and troubleshooting advice within these platforms.

Searching specific forums using keywords like “walk-in freezer wiring,” “cooler schematic,” or the specific model number can yield relevant results. While information sourced from forums should be verified, it can be helpful when manufacturer documentation is unavailable.

Be cautious and cross-reference any diagrams found with other sources. Community-sourced information may not always be entirely accurate. Active participation and asking specific questions can also connect you with knowledgeable individuals willing to assist in locating the correct wiring diagram for your unit.

Online Diagram Databases

Several online databases specialize in collecting and distributing technical diagrams, including walk-in freezer wiring schematics. These platforms often require a subscription or one-time payment to access their full library of documents. However, they can provide a centralized location for finding diagrams from various manufacturers.

Popular databases may include electrical schematics, parts lists, and service manuals. Searching by manufacturer, model number, or component type is crucial for narrowing down the results. Always verify the diagram’s compatibility with your specific walk-in freezer model before relying on it for wiring work.

Ensure the database is reputable and regularly updated to guarantee the accuracy of the information provided. Some databases also offer user forums where you can seek assistance or clarification on specific diagrams.

Interpreting a Walk-in Freezer Wiring Diagram

Decoding diagrams involves understanding symbols, tracing circuit paths, and correctly identifying each component—essential skills for safe and effective walk-in freezer maintenance.

Understanding Symbols

Walk-in freezer wiring diagrams utilize standardized symbols representing electrical components. Recognizing these is fundamental to interpretation. A circle often denotes a relay or contactor, while a square signifies a switch. Capacitors are depicted with two parallel lines, and resistors with a zig-zag pattern.

Compressors are commonly shown as sealed units, and motors as circles with windings. Thermal overloads are represented by a symbol indicating heat sensitivity. Grounding symbols, essential for safety, are typically depicted as three horizontal lines decreasing in length. Understanding these symbols, alongside line types (solid for power, dashed for control), allows for accurate circuit tracing. Referencing a symbol key accompanying the diagram is always recommended for clarity and to avoid misinterpretation during troubleshooting or repair work.

Tracing Circuits

Effectively tracing circuits within a walk-in freezer wiring diagram PDF begins at the power source – typically a fused disconnect switch; Follow the line representing the hot wire through the diagram, noting each component it connects to, such as the compressor, defrost timer, and fan motors.

Pay close attention to control circuits, often depicted with dashed lines, which govern the operation of these components. Identify the path of the signal from the temperature controller to the defrost timer and other devices. Use a multimeter to verify continuity along the traced path, confirming connections and identifying breaks. Systematically tracing circuits ensures a comprehensive understanding of the electrical flow and aids in pinpointing the source of any malfunctions.

Identifying Components

A walk-in freezer wiring diagram PDF utilizes standardized symbols to represent each electrical component. Accurately identifying these is crucial for understanding the system. Locate the compressor symbol, often depicted as a sealed unit, and trace its connections. Recognize the defrost timer, responsible for initiating defrost cycles, and its associated heater.

The temperature controller, like a Dixell XR06CX, will have a specific symbol indicating its inputs and outputs. Fan motors are typically shown as circular symbols with windings. Door heater elements and their controls are also clearly marked. Refer to the diagram’s legend to confirm symbol meanings, ensuring correct component identification for troubleshooting and repair.